The world of optics is a realm of precision and innovation, and at its core, lies the art and science of designing custom aspheric optics. These optical components are meticulously crafted to meet specific needs, pushing the boundaries of optical performance. In this article, we will take a deep dive into the intricate process of designing custom aspheric optics, exploring the principles, challenges, and essential considerations that define optical engineering.

Understanding Aspheric Optics

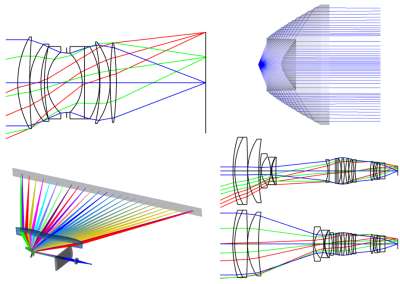

Aspheric optics, as opposed to conventional spherical lenses, have surfaces that deviate from a simple spherical shape. This deviation allows them to correct optical aberrations, leading to improved performance in various applications. Aspheric lenses are particularly valuable in imaging, laser systems, and optical instruments.

Principles of Designing Custom Aspheric Optics

Designing custom custom aspheric lenses is a complex task that follows several key principles:

- Aberration Correction: The primary objective is to correct optical aberrations, including spherical aberration, coma, astigmatism, and distortion. These aberrations can distort images and degrade optical performance, so aspheric optics aim to minimize or eliminate them.

- Focal Length and Aperture: Custom aspheric lenses are designed with specific focal lengths and aperture sizes in mind, tailored to the intended application. Precise control over these parameters ensures that the lens meets the desired performance criteria.

- Wavelength Considerations: The design must account for the spectral characteristics of the light used in the application. Different wavelengths of light can behave differently when interacting with aspheric surfaces, so the design must accommodate the desired wavelength range.

- Materials Selection: Choosing the appropriate optical material is crucial. The material should have the desired optical properties and be compatible with the environmental conditions of the application.

- Manufacturability: The design should take manufacturability into account. It’s essential to create a design that can be fabricated with existing technologies and processes while maintaining the required level of precision.

Challenges in Designing Custom Aspheric Optics

Designing custom aspheric optics comes with its share of challenges:

- Complex Surface Profiles: Aspheric surfaces can have highly complex profiles, making their design and fabrication more challenging than traditional spherical lenses. Achieving the desired surface shape with high precision requires advanced manufacturing techniques.

- Tolerances and Sensitivity: Aspheric optics are often more sensitive to manufacturing tolerances and environmental factors than spherical lenses. The design must consider these sensitivities to ensure the lens functions as intended under various conditions.

- Iterative Optimization: Designing custom aspheric optics often involves an iterative optimization process. Engineers refine the design through multiple iterations to achieve the desired optical performance.

Considerations in Optical Engineering

Optical engineers carefully consider various factors when designing custom aspheric optics:

- Performance Metrics: Engineers define performance metrics specific to the application, such as image quality, resolution, and aberration control. These metrics guide the design process.

- Ray Tracing: Ray tracing simulations are often used to evaluate the optical performance of the design. This helps identify potential issues and refine the aspheric surface profiles.

- Cost-Effectiveness: Balancing performance with cost is critical. Engineers aim to achieve the desired optical performance while optimizing the design for cost-effective manufacturing.

- Environmental Factors: Engineers consider the environmental conditions the optics will encounter, such as temperature variations, humidity, and vibration, to ensure the optics can withstand these conditions.

Applications of Custom Aspheric Optics

Custom aspheric optics find applications across various industries, including:

- Photography: High-quality camera lenses often incorporate custom aspheric elements to reduce optical aberrations, resulting in sharper and distortion-free images.

- Laser Systems: Aspheric optics are crucial in laser systems, where they help focus and shape laser beams with high precision for applications like laser cutting, engraving, and medical lasers.

- Telescopes and Microscopes: Aspheric optics improve image quality and reduce optical aberrations in telescopes and microscopes, allowing for more detailed observations in astronomy and life sciences.

- Optical Instruments: Custom aspheric optics are used in a wide range of optical instruments, such as spectrometers, interferometers, and optical systems used in scientific research.

In conclusion, designing custom aspheric optics is a complex and precise endeavor that requires a deep understanding of optical principles, engineering expertise, and a dedication to achieving optimal performance. These optical components enable groundbreaking advances in imaging, laser technology, and scientific research, pushing the boundaries of what is possible in the world of optics. As technology continues to evolve, custom aspheric optics will remain at the forefront of innovation, enhancing our ability to capture and manipulate light for various applications.